|

| May 20, 2014 | Volume 10 Issue 19 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox:

Seamless, morphing plane wing technology introduced by FlexSys

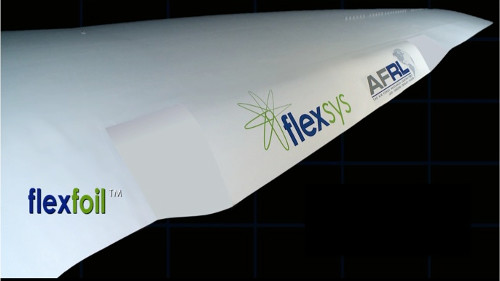

A Michigan company called FlexSys demonstrated its FlexFoil seamless morphing-wing control technology at the AIAA convention in Washington, DC, earlier this year. The creation of a variable-geometry airfoil has been a long-sought target chased by the defense and commercial aviation industries and researchers for several decades. Traditional mechanical wing flaps that slide in and out and move up and down could ultimately be a thing of the past with the new design, but for now Flexsys is proposing retrofit sliding sub-flaps that provide span-wise twist to increase fuel efficiency.

The FlexFoil replaces jointed wing flaps with a deformable, seamless surface that changes shape for optimized performance throughout the flight regime, saving jet fuel. From the outside, the wing looks like a single solid structure, but one that can bend and deform with precise control.

Changing the shape of a modern aircraft's wing in flight has been an elusive goal. Unlike the earlier iterations, which suffered from complexities with the actuators and problems of heavyweight componentry, the FlexFoil control surface technology employs a new approach, called distributed compliance, to achieve practical variable geometry wings that are lightweight, reliable, and cost effective.

Replacing trailing-edge flaps of a Gulfstream Business jet with FlexFoil seamless control surfaces, several flight tests are scheduled by NASA at its Dryden Flight Research Center, in collaboration with Air Force Research Labs (AFRL), in July 2014. In retrofit applications, FlexSys says the technology can cut fuel consumption by 4 percent to 8 percent, and that number can grow to 12 percent or more in clean-sheet builds. Other benefits of the technology include significant noise reduction (up to 40 percent during landing) and lowered maintenance costs due to reduced wing loads.

Dr. Sridhar Kota, a mechanical engineering professor at the University of Michigan, pioneered the method of Distributed Compliance -- a form of structural load sharing by exploiting elasticity to design monolithic compliant structures, which are also called joint-less mechanisms. Starting in 2001, he focused the efforts of his newly formed FlexSys company toward practical applications of his patented technology, and with funding from AFRL proved the viability of his designs through various tests to confirm structural integrity and enhanced aero performance.

FlexSys' design demonstrates wing morphing at practical scales. For instance, as a complete replacement of conventional trailing-edge flaps on a Gulfstream Business Jet, FlexFoil seamless control surfaces each extend 14 ft span-wise along with 2-ft-long seamless transition sections on both ends, offering a camber change from -9 deg to 40 deg as well as span-wise twist at high rates (up to 50 deg/sec). The FlexFoil control surface is strong and stiff enough to support well over 10,000 lb of air loads.

"FlexSys' FlexFoil technology could enable long-sought aerodynamic benefits of variable-geometry wings to be realized on a variety of aircraft without a high degree of structural and control complexity," says Peter Flick, program manager at AFRL Wright-Patterson Air Force Base, Ohio. His team has been working with FlexSys on the FlexFoil technology for several years.

Dr. Terry Weisshaar, a world-renown researcher and retired Purdue University professor and program manager for the Defense Advanced Research Projects Agency (DARPA) Morphing Aircraft Structures, says, "FlexSys has taken an innovative 'distributed compliance' approach and created a flight-qualified, operationally safe, reliable, and efficient new morphing sub-system to change the shape of future aircraft systems to improve system efficiency and capability."

Using aerospace-grade materials and actuators in its design, FlexFoil's variable geometry design greatly exceeds the life cycles required of commercial aircraft flaps, and it can be applied to other control surfaces such as leading edge, engine inlets, and vertical and horizontal stabilizers. It also has the potential to revolutionize helicopter rotor design. FlexSys has already produced prototypes of variable-geometry leading and trailing edges for helicopter rotor blades for potential increases in forward speed, payload, and noise reduction.

Given the United States' aviation community's $54 billion yearly fuel bill, these savings are being viewed enthusiastically by industry insiders in both the manufacturing and operations spheres. Successful flight tests of the new FlexFoil technology are expected to gain the attention of designers and accountants.

"The potential to save fuel is tremendous with the variable-geometry wing," says Dr. Kota. "There is the direct savings due to the reduction in drag provided by the adaptive seamless surface, but there is also a complementary gain in control authority and load alleviation.

Analysis and experimental results have demonstrated that by retrofitting even a variable-geometry trailing edge sub-flap, rather than a complete flap replacement, 4 percent to 5 percent fuel savings can be realized. The FlexFoil's ability to twist the control surface span-wise reduces wing stresses, which in turn allows the use of winglets on existing aircraft without requiring costly structural modifications to the wing, which can further cut fuel use by another 6 percent."

While the aircraft wing application was a focal point of the AIAA show, FlexSys purports that any object moving relative to a fluid medium, such as helicopters, wind turbine blades, sailboats, automobiles, and pumps, could potentially benefit from FlexFoil variable geometry technology.

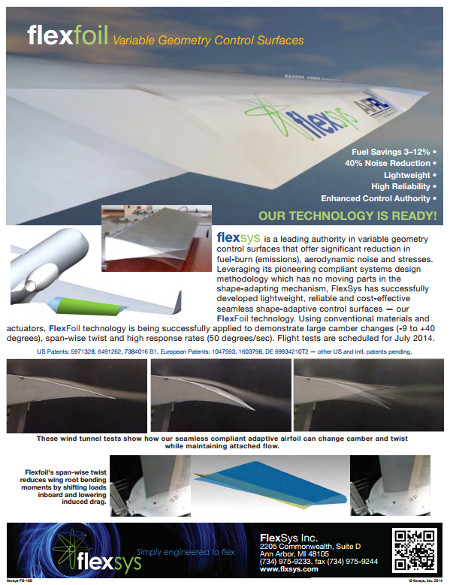

FlexSys has provided a two-page PDF takeaway document (shown above) that details the sub-flap design. You can access it here.

Source: FlexSys

Published May 2014

Rate this article

View our terms of use and privacy policy